Integra TX

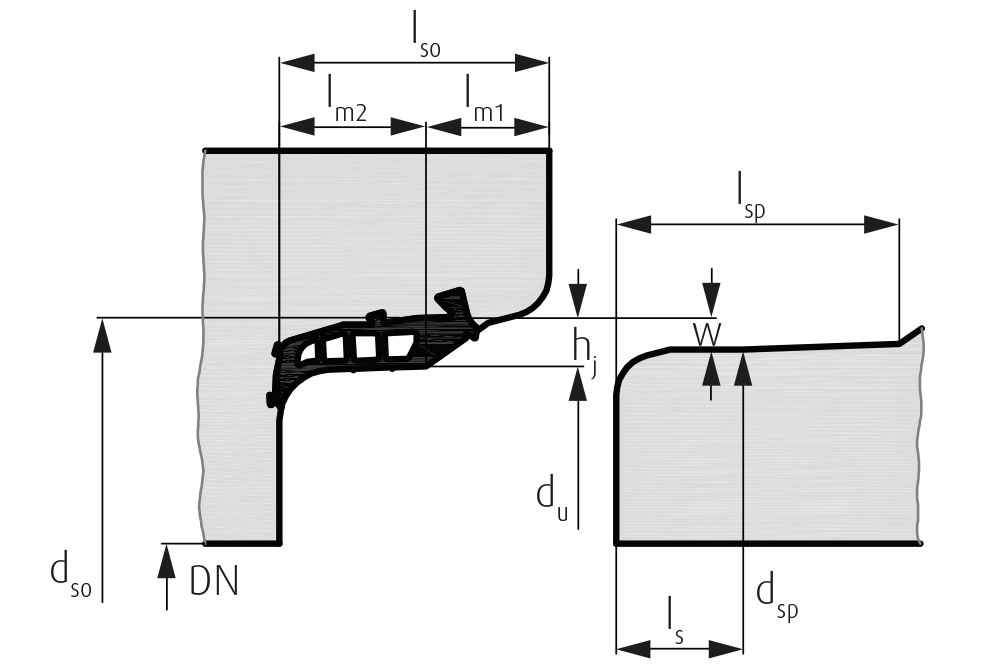

for concrete pipes | Ø 300-1200 mm

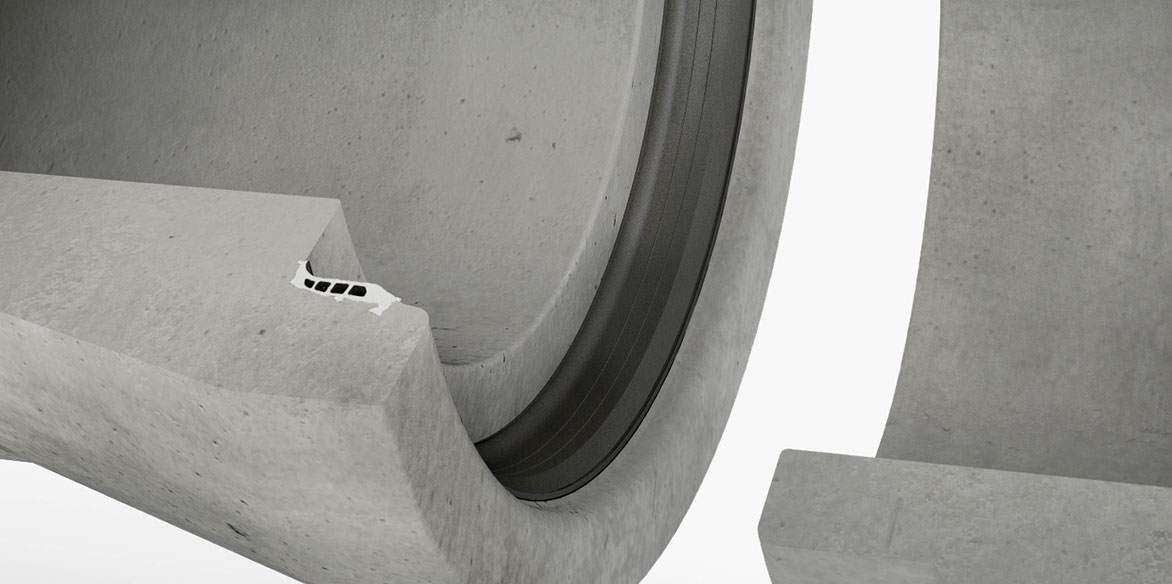

The M.O.L. INTEGRA TX concrete pipe seal is integrated into the socket and guarantees a firm, reliable connection between concrete pipes and reinforced concrete pipes in compliance with DIN EN 1916. In addition the INTEGRA TX seal meets the requirements of EN 681-1 and the FBS quality guideline QR 4060®.

Material

The seal is made of SBR (styrene-butadiene rubber) which is ideal for use in sewage systems and complies with the requirements of the DIN EN 681-1 WC 50 standard (Hardness 50 ± 5 IRHD). Our INTEGRA TX seal is tested and inspected for quality by MPA NRW (Dortmund).

Pipe manufacture

Fit the INTEGRA TX seal onto the cleaned base ring. The base ring should be lightly lubricated. Fill the socket with concrete and then start sealing. Subsequently cast the concrete pipe in the customary manner. After removing the pipe from the form, place the outer and inner support ring onto the spigot and remove from the form with the base ring when the concrete has set. When the concrete has fully set, the spigot and socket pipe with the INTEGRA TX seal is ready for use.

Note for pipe installation

Before joining the pipes, grease the spigot and seal thoroughly with a suitable lubricant (also available from M.O.L.). Centre and insert the spigot into the socket and pull the pipes together.

Advantages

- exact contour-parallel contact surface on cleaned base ring

- optimum tightness by matched material components through increased inboard material as well as outer layer and smooth wedge

- excellent radial and vertical rigidity

- economically seal through less volume and weight

- tightness up to 2,5 bar / water protection arealm2wdudsoDNhjlm1lsolsdsplsp